Characteristics of the Product

- UL Certificate Approval

- Possible to produce with a roll grooving product

- Reduction of material costs compared to the existing TEE

Merits of the Product

Economic Feasibility

- Reduction of material costs compared to the existing TEE

- Reduction of construction cost due to the reduction of welding inch

- Reduction of work time and labor cost through simple construction

Safety

- Reduction of leakage risk due to the reduction of welding volume

- Reduction of leakage risk due to the reduction of connecting areas with groove coupling

- Possible to respond promptly to defects (possible to redo the construction after dissembling the joint area)

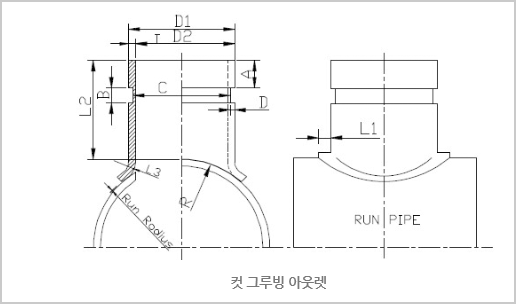

Standards

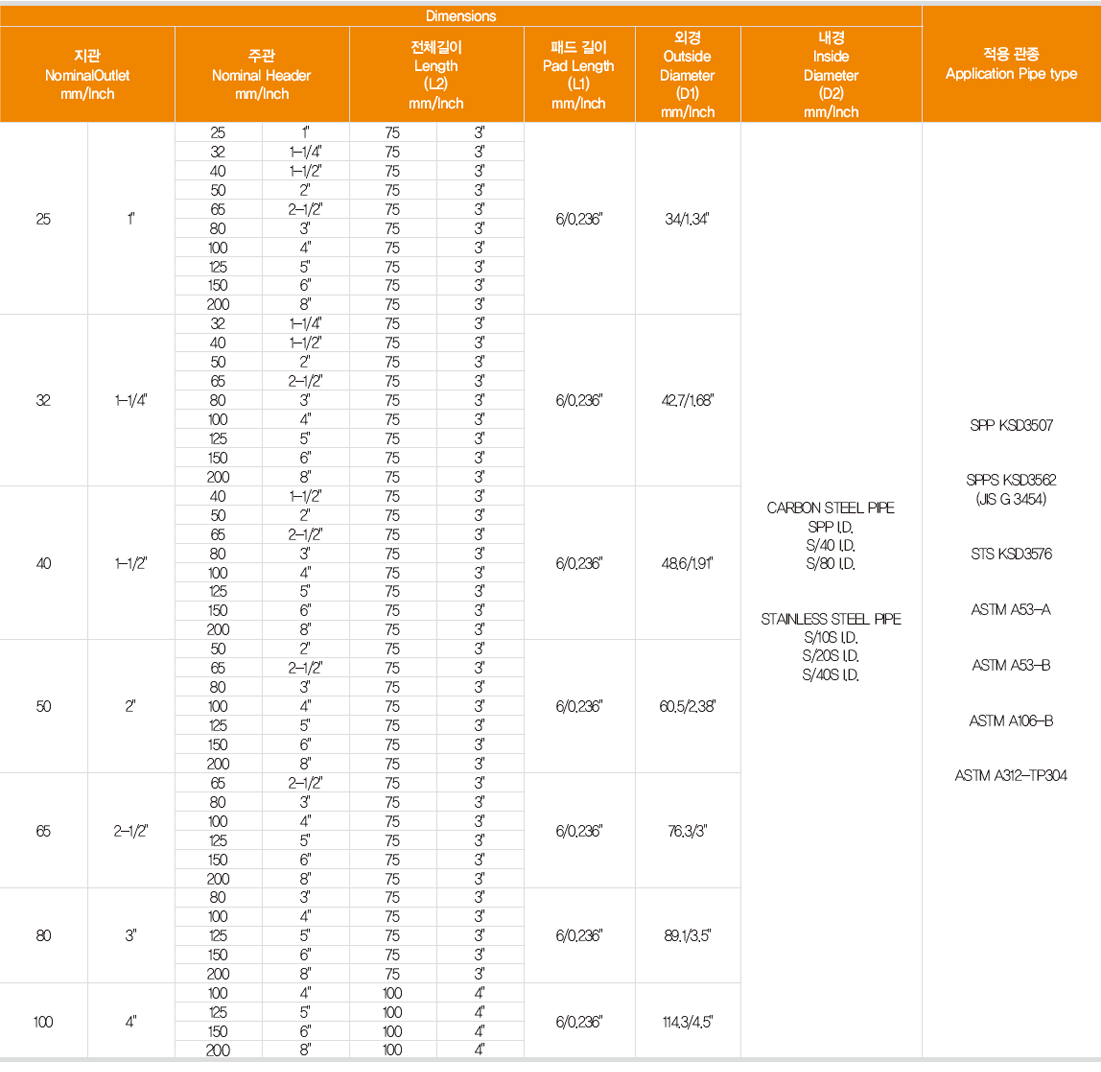

* For UL specifications, possible to manufacture up to main pipe 300

* The above standards may be partially changed to improve technology and quality.

* Above specifications are UL standards and contact us for KFI standards.

성능시험결과

Test Item |

Test Standard(KFI) |

PLS |

KFI |

Pressure-Resistance Test |

When applying 1.5 times of the maximum operating pressure, there should be no cracks, permanent deformation or damage. |

2.1MPa | pass |

Body Strength Test |

When applying 5 times pressure of the highest operating pressure (higher than 1.4MPa), there should be no cracks, permanent deformation or damage. |

7MPa | pass |

Test Item |

Test Standard(UL)) |

PLS |

UL |

Leakage Test |

When applying twice pressure of the highest operating pressure (300 PSI), there should be no cracks, permanent deformation or damage. |

600 PSI(4.14MPa) | pass |

Pressure-Resistance Test |

When applying 4 times pressure of the highest operating pressure (300 PSI), there should be no cracks, permanent deformation or damage. |

1200 PSI (8.27MPa) | pass |

Body Strength Test |

When applying 5 times pressure of the highest operating pressure (300 PSI), there should be no cracks, permanent deformation or damage. |

1500 PSI (10.34MPa) | pass |